Solution for aluminium forming machines project in Nigeria market

Solution for aluminium forming machines project in Nigeria market

Solution background

Buyer is one real estate developer and spending too much to buy for his houseing projects. And he can not control delivery time of tile and long span sheet. One real estate developer, his housing projects require at least three main product: long span roll forming machine to produce roof, step tile roll forming machine to produce tile, and metrocopo roll forming machine to make metrocopo tile.

So we suggest he starts from three machines. Adding one forklift to operate his machines in his factory.

Deatails is following:

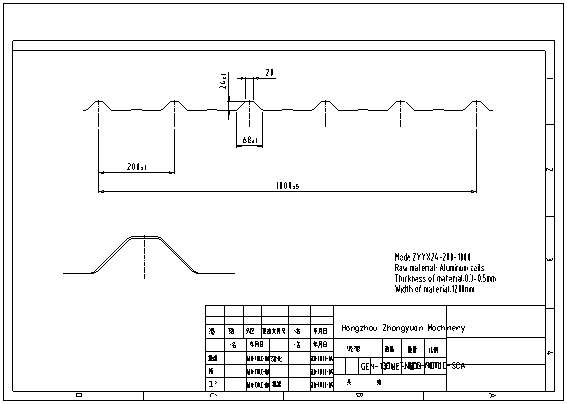

1;Long Span roll forming machine (European style) :

Long span drawing

Long span sample

Long span machine photo (European style)

Long span machine MAIN PARAMETERS:

1) Forming Speed | Max. About 25m/min. (excluding the cutting time) | ||

2) Main Motor Power | 5.5KW (Depend on final design) | ||

3) Hydraulic Station Power | 2.2KW (Depend on final design) | ||

4) Control System | Mitsubishi PLC and transducer,Mitsubishi screen (Japanese brand) | ||

5) Encoder: | Nemicon (Japanese brand) | ||

6) Rollers’ material | High grade No.45 forged steel, with digital-controlled procession, plated with chrome on surface. | ||

7) Shaft diameter | 72mm, tooled by grinding machine for two times to ensure the precision of final product. | ||

8) Type of Cutting | Length-set cutting and post forming style | ||

9) Electric Condition | 380V/3Phase/50HZ(or depend on customer) | ||

10) Total Weight | About 8500 Kg | ||

11) Machine size | About 9X1.7X1.6m (lengthXwidthXheight) | ||

Full automatic PLC Control System

MACHINE COMPONENTS

(1) Manual decoiler | 1 set(Capacity: 5 tons) | |

(2) Roll-Forming M/C | 1 set | |

(3) Hydraulic Cutting | 1 set | |

(4) Hydraulic station |

1 set |

|

(5) PLC Control System |

1 set |

|

(6) Tool Box |

1 piece |

|

2;Step tile roll forming machine :

step tile machine drawing

Step tile machine photo (European style)

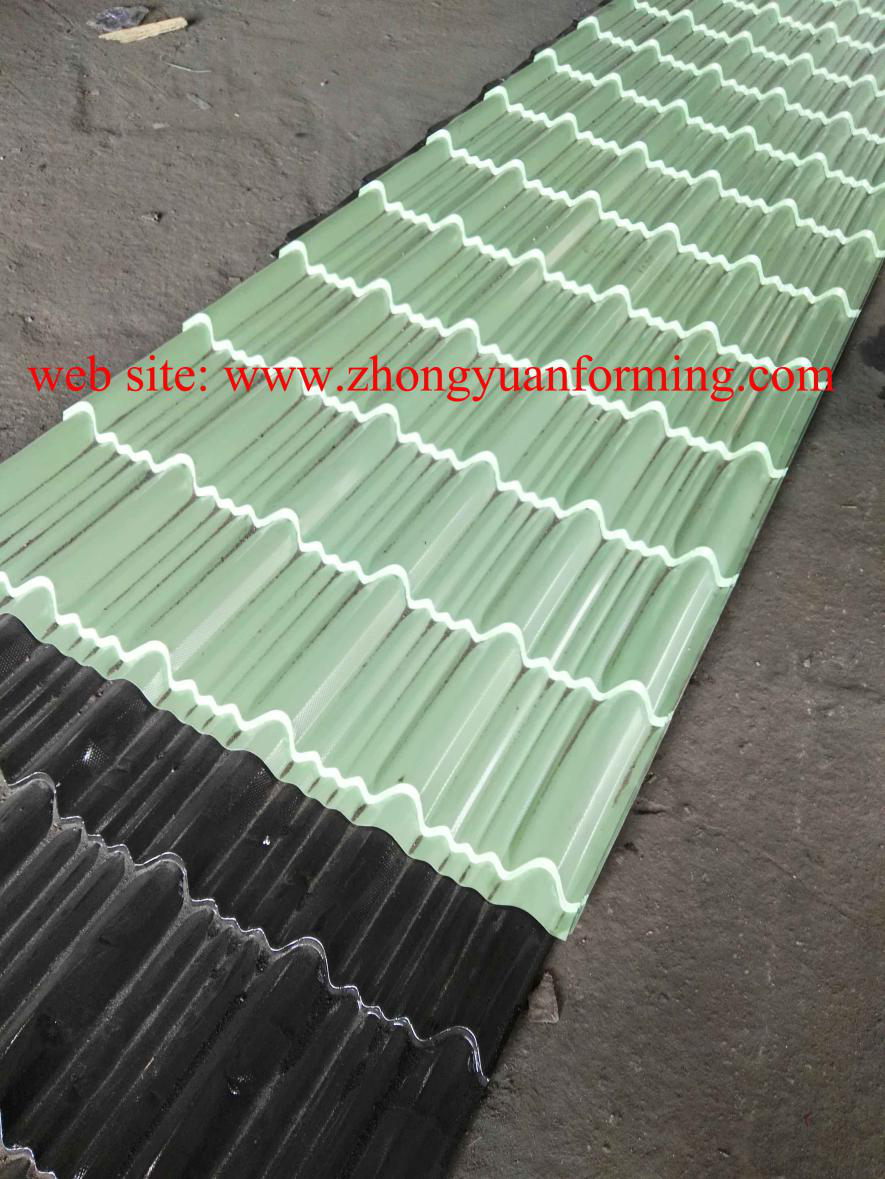

Step tile sample

Step tile sample

MAIN PARAMETERS for Step tile machine

1) Working Speed | About 6m/min. (including the cutting& pressing time | ||

2) Main Motor Power | 5.5KW (Depend on final design) | ||

3) Hydraulic Station Power | 5.5KW (Depend on final design) | ||

4) Control System | Mitsubishi PLC, transducer and Mitsubishi screen (Japanese brand) | ||

5) Encoder | Nemicon (Japanese brand) | ||

6) Rollers’ material |

High grade No.45 forged steel, with digital-controlled procession,plated with chrome on surface. |

||

7) Shaft diameter |

72mm, tooled by grinding machine for two times ,to ensure the precision of final product |

||

8) Type of Cutting |

Length-set cutting and post forming style |

||

9) Electric Condition |

380V/3Phase/50HZ(or depend on customer) |

||

10) Total Weight | About 11500 Kg | ||

Full automatic PLC Control System

MACHINE COMPONENTS

(1) Manual decoiler | 1 set(Capacity: 5 tons) | |

(2) Roll-Forming M/C |

1 set |

|

(3) Hydraulic pressing device | 1 set | |

(4) Hydraulic Cutting | 1 set | |

(5) Hydraulic station |

1 set |

|

(6) PLC Control System |

1 set |

|

(7) Tool Box |

1 piece |

|

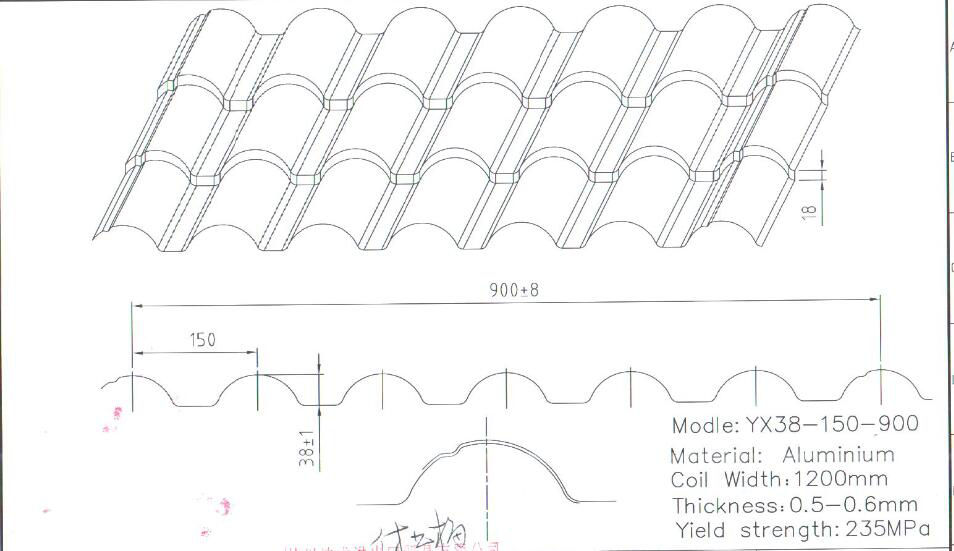

3;Metrocopo tile roll forming machine

Metrocopo tile machine drawing

Metrocopo tile machine photo (European style)

Metrocopo tile sample

Metrocopo tile sample

MAIN PARAMETERS for Metrocopo tile machine

1) Working Speed | About 6m/min. (including the cutting& pressing time) | ||

2) Main Motor Power | 5.5KW (Depend on final design) | ||

3) Hydraulic Station Power | 5.5KW (Depend on final design) | ||

4) Control System | Mitsubishi PLC, transducer and Mitsubishi screen (Japanese brand) | ||

5) Encoder | Nemicon (Japanese brand) | ||

6) Rollers’ material | High grade No.45 forged steel, with digital-controlled procession, plated with chrome on surface. | ||

7) Shaft diameter |

72mm, tooled by grinding machine for two times to ensure the precision of final product. |

||

8) Type of Cutting |

Length-set cutting and post forming style |

||

9) Electric Condition | 380V/3Phase/50HZ(or depend on customer) | ||

10) Total Weight | About 11500 Kg | ||

Full automatic PLC Control System

MACHINE COMPONENTS

(1) Manual decoiler | 1 set(Capacity: 5 tons) | |

(2) Roll-Forming M/C | 1 set | |

(3) Hydraulic pressing device | 1 set | |

(4) Hydraulic Cutting |

1 set |

|

(5) Hydraulic station |

1 set |

|

(6) PLC Control System |

1 set |

|

(7) Tool Box |

1 piece |

|

4;Forklift : Hangcha Forklift ( Famous brand in China, who is one stock group company, ensure good quality)

CPCD30N-RW15A,NISSAN transmit system

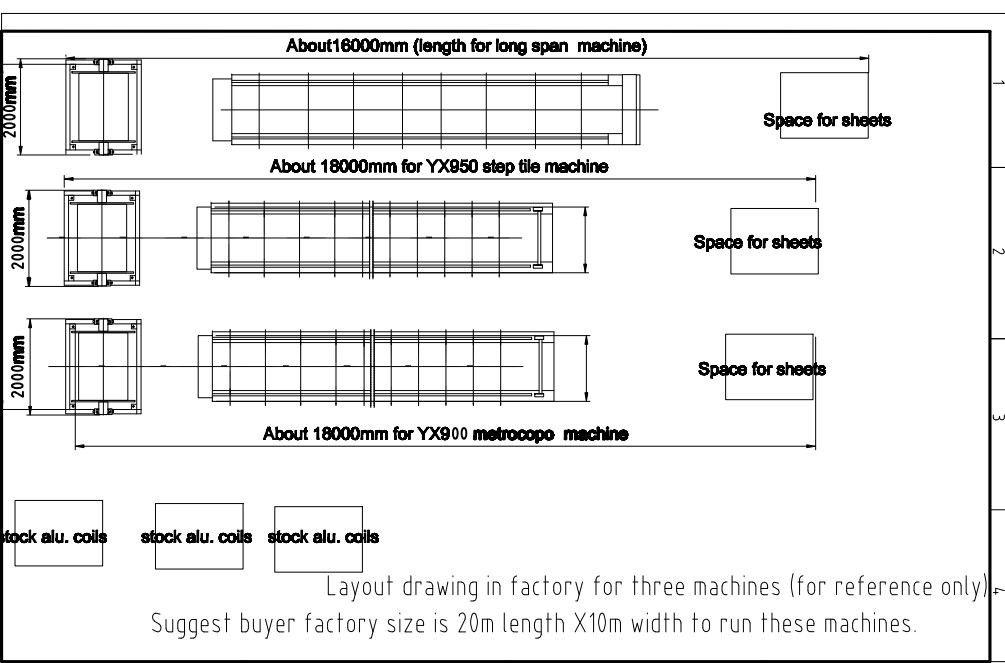

Buyer factory size requirement: 20m length X 10m width.

From above plan, buyer should prepare for at least USD135000 for machines and forklift.And this payment doesn’t include fee which buyer should pay to Nigeria custom tax and clearing cost in Tincan port. Buyer can get this custom tax and clearing cost from Nigeria clearing agent.

Zhongyuan can supply all required machines and forklift and aluminium coils for buyer. Buyer only prepares for factory site and money to wait for his project starting.

Choose Zhongyuan forming machine, forming your dream!

Hangzhou Zhongyuan Machinery Factory

Wechat/ whatsapp number: 0086-13867521382

- Phone

- *Title

- *Content